In the 95 years since the birth of the brand, VOLVO has always adhered to the principle of safety. On the premise that users do not need to change their usage habits, some models of VOLVO have added a set of 48V lithium-ion battery hybrid power system, and the one responsible for managing this set of battery is the BMS (battery management system) we often mentioned. At present, the XC60 B5 model, which is favored by the elite, adopts the diverter manufactured by the industry exhibition on the BMS monitoring version.

According to the data in the Technical Roadmap 2.0 of Energy-saving and New Energy Vehicles, by 2025, China's hybrid vehicles will account for more than 50% of the traditional energy passenger vehicles, and by 2035, energy-saving vehicles will be fully hybrid, and the hybrid vehicles will account for 100% of the traditional energy passenger vehicles. On the other hand, in the global environment of energy conservation and emission reduction, the emission standards of commercial vehicles in various countries are gradually tightened, which forces automobile enterprises to transform some fuel vehicles into new energy.

However, due to the current technical difficulties, it is basically impossible to achieve the emission target solely by improving the fuel efficiency of the engine. If it is completely transformed into pure electricity, it means not only technological transformation, but also the abandonment of some fuel vehicle production lines, technology, talent, supply chain and other resources accumulated over the years. In this case, as a 48V light hybrid system between fuel and pure electricity, it can make small changes to traditional fuel vehicles, lower system costs, and achieve obvious energy-saving effects, making it a new hot spot in the industry. It is a good choice for traditional vehicle enterprises, and also the first step of electrification transformation for traditional vehicle enterprises.

In recent years, major luxury brands such as Benz, BMW, Audi, Volvo and Cadillac have successively installed 48V light hybrid system on their main models, which has been ignored, returned to the market, and now is used by major car companies. At present, battery enterprises such as Ningde Times, Wanxiang A123, Yiwei Lithium Energy, Xinwanda, Guoxuan Hi-Tech have all deployed 48V batteries, and Wanxiang has started the 48V project as early as 2013, and then acquired A123, which has occupied a part in the 48V field since then. The 48V system of Wanxiang A123 can assist the vehicle to complete the functions of intelligent start and stop, acceleration assistance and braking energy recovery, reaching the world's leading level in the extreme experience of high fuel saving rate and excellent power.

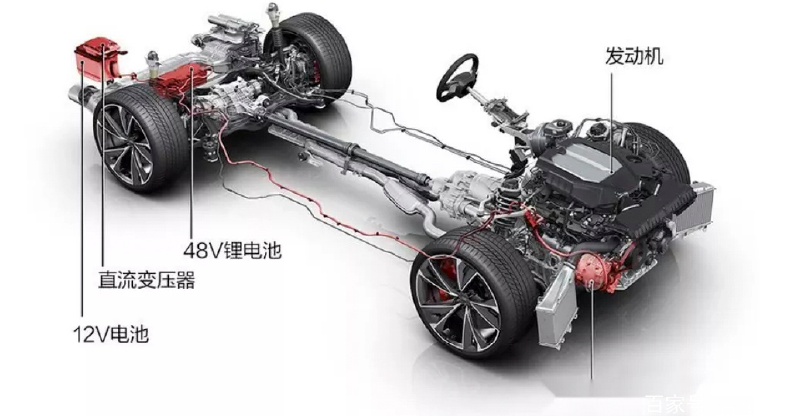

So what is the 48V light hybrid system?

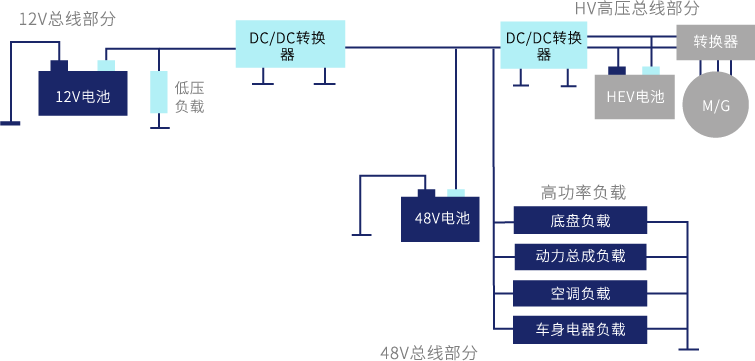

Since the vehicle battery voltage has been raised from 6V to 12V, it has been widely used up to now. However, with the diversification and intellectualization of automotive electronic equipment, 12V is not enough to deal with various automotive electronics. For example, hydraulic power steering pump and cooling circulating water pump are all replaced by electric motors. In addition, complex intelligent interactive system, brake by wire, adaptive cruise, all-vehicle radar and other configurations urgently need to improve power consumption. The 48V voltage not only conforms to the human body safety voltage of 60V (according to the provisions of the automobile safety standard ECE-R100, it needs to increase the corresponding protection when it exceeds the human body safety voltage, which will increase various costs), but also supports the use of higher power automotive electronic equipment, so 48V becomes the first choice.

The 48V system is based on the original 12V system, and an additional 48V system is added for other functions requiring higher power. The standard 48V system is composed of motor, battery pack and DC-DC converter.

Advantages of 48V light mixing system:

The safety voltage is lower than 60V, no additional voltage protection is required, and the cost is lower than that of high-voltage hybrid system;

Compared with the 12V system, the working current is only 1/4 and the loss is only 1/16 of the 12V system at the same power;

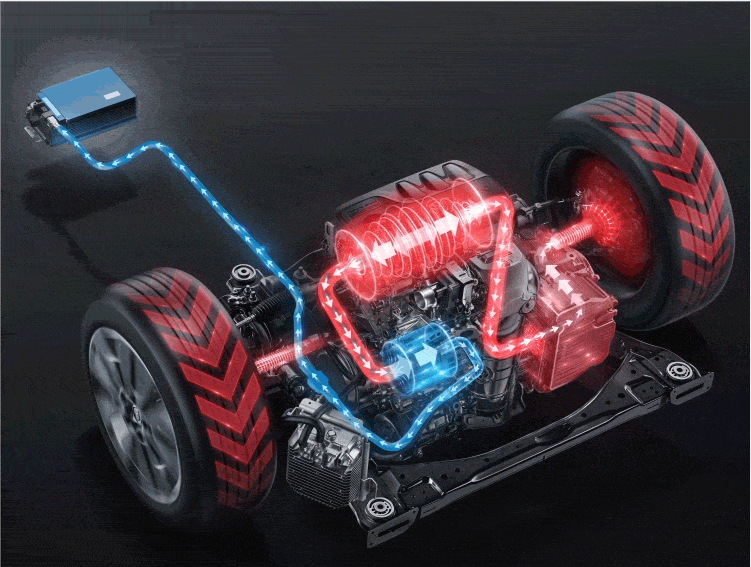

Due to the electric power assistance of BSG/ISG, the engine volume can be further reduced, thus reducing emissions;

High-load accessories on traditional engines can be electrified, such as air conditioning compressor, cooling water pump, vacuum pump, etc., to reduce the load of the engine. These equipment can work even when the engine is shut down;

Raising the working voltage of the on-board electrical appliance to 48V can further reduce the loss and reduce the outer diameter of the harness;

It can support higher power on-board equipment;

It can be turbocharged to further improve the efficiency of the engine, and there will be no delay of turbocharger;

The 48V Belt Starter Generator (BSG) can easily replace the original 12V Belt Starter Generator, and can be matched without major design changes.

The precision alloy diverter developed by Yezhan Electronics has the characteristics of high precision, high power and high stability. It can load different currents (up to 1000A), wide operating temperature range (- 55~170 ℃), and extremely high long-term stability (up to 2/10000 change rate). Long-term stability provides high current detection application for battery BMS, monitors the limit conditions such as overcurrent and short circuit, and provides guarantee for the safety and durability of the entire battery system. At the same time, we support one-to-one customer customization, and carry out customized structural design and functional design according to the actual needs of customers.

Yezhan Electronics has been focusing on precision alloy resistors for 19 years. With its advanced R&D concept, professional technical team, superior product performance and careful customer service, its products sell well both at home and abroad, and it is a strategic partner of many internationally renowned enterprises.